How to Repair Your Clock

Posted: Tue Jul 13, 2010 2:57 pm

My clock like so many others had stopped working, so I set about trying to find out what was wrong with it.

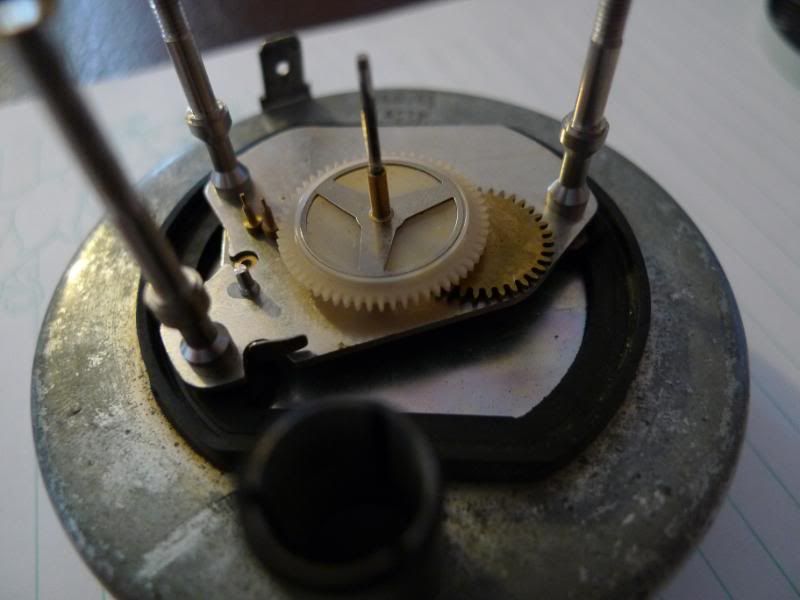

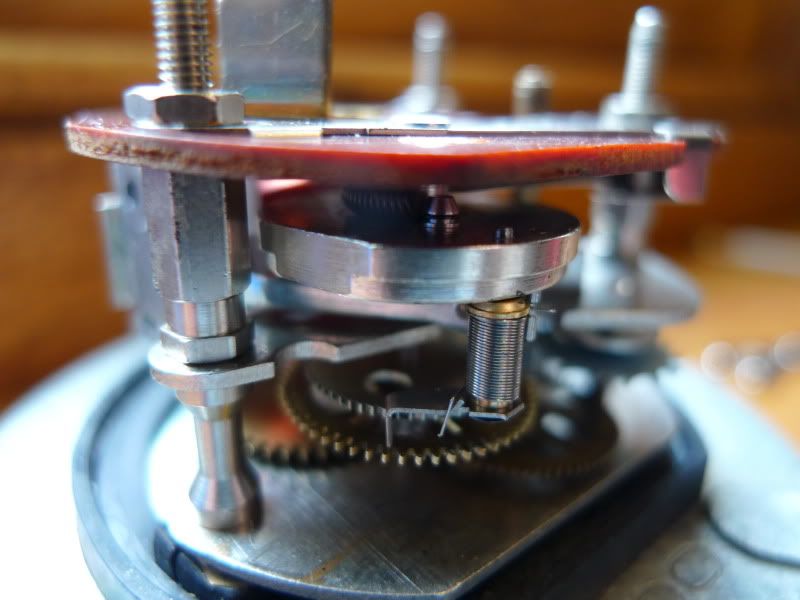

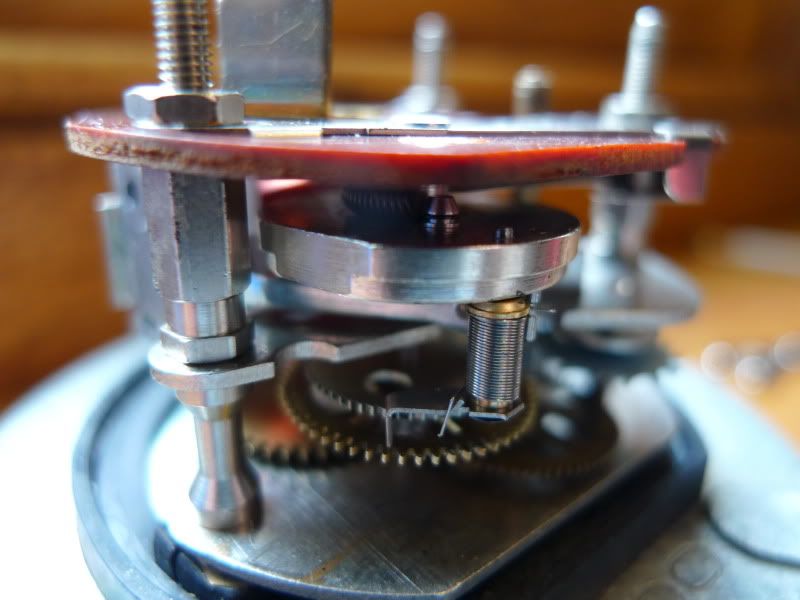

To remove from the car you just pull the clock out from the dashboard. remove the 12volt black wire and the brown earth wire. Once out of the car you can remove the white plastic from the rear of the clock with a 5mm spanner. This exposes the workings. You need to remove the upper most electro magnetic winder board. This is simply done by removing the three 5mm nuts, when lifting this off be careful not to damage the ratchet on the winder.

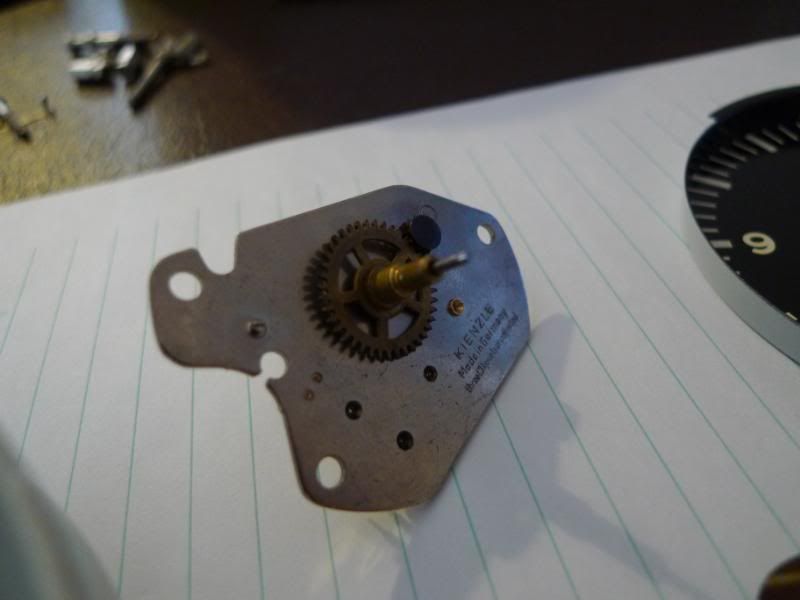

Once this was removed I was able to see why the clock had stopped working, the bearing for the winding gear was worn out, it was elongated and about three time the size of the shaft.

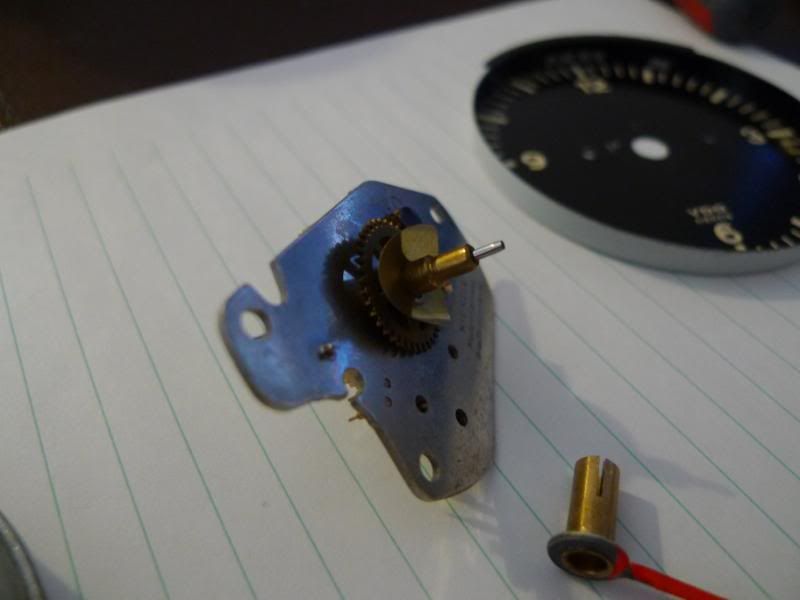

You can remove the upper bearing plate by removing the three 4.5mm spacer nuts. Before you pull the top bearing plate off be aware that the balance wheel is attached to the plate by its wound spring, if you do not support this you will damage it.

Once the plate is removed you can remove all of the gear wheels.

Once all the gear wheels are removed you can inspect the bottom bearing plate on inspection the bottom bearing on the winding gear was again worn out, and elongated.

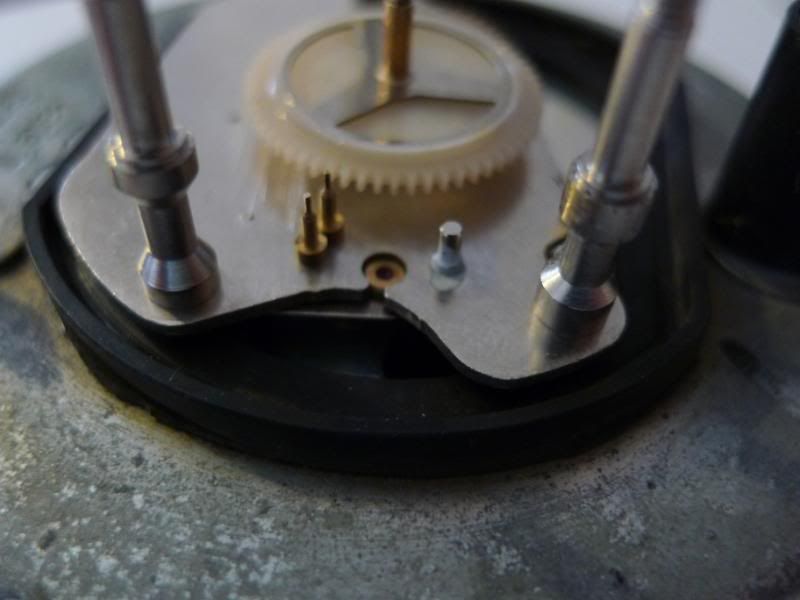

To gain access to this you need to remove the front bezel, you have to use a small screw driver to bend the back up so you can remove the glass and bezel. You need to remove the hands of the clock, to do this I had to use a pointer puller with a modified point, I did this at work and did not have a camera but you need to pull the minuet hand off first then the hour hand. Once the hands are off you can remove the two black screws holding the face on. Hopefully you can work out what I mean by this photo.

To remove from the car you just pull the clock out from the dashboard. remove the 12volt black wire and the brown earth wire. Once out of the car you can remove the white plastic from the rear of the clock with a 5mm spanner. This exposes the workings. You need to remove the upper most electro magnetic winder board. This is simply done by removing the three 5mm nuts, when lifting this off be careful not to damage the ratchet on the winder.

Once this was removed I was able to see why the clock had stopped working, the bearing for the winding gear was worn out, it was elongated and about three time the size of the shaft.

You can remove the upper bearing plate by removing the three 4.5mm spacer nuts. Before you pull the top bearing plate off be aware that the balance wheel is attached to the plate by its wound spring, if you do not support this you will damage it.

Once the plate is removed you can remove all of the gear wheels.

Once all the gear wheels are removed you can inspect the bottom bearing plate on inspection the bottom bearing on the winding gear was again worn out, and elongated.

To gain access to this you need to remove the front bezel, you have to use a small screw driver to bend the back up so you can remove the glass and bezel. You need to remove the hands of the clock, to do this I had to use a pointer puller with a modified point, I did this at work and did not have a camera but you need to pull the minuet hand off first then the hour hand. Once the hands are off you can remove the two black screws holding the face on. Hopefully you can work out what I mean by this photo.