Page 1 of 1

MFI throttle bushings and set up

Posted: Thu Nov 24, 2022 9:31 pm

by rft218

Hi All,

I am trying to synchronise my throttles on a newly rebuilt engine. I originally had a schoolboy error as I had mistimed my fuel pump which is now corrected and made a big difference!!

It now runs ok but just trying to synchronise it with a meter. Has anyone got experience of this. In the Porsche CMA manual they go straight from setting the rod lengths to running the engine at 3000rpm to and adjusting the air bleed screws, presumably after setting the idle stops by finding where they 'pinch' and backgin off 1/2 turn, but in another document the person sets the idles first by adjusting the idle stops with the rods off and doesnt seem to get into the air bleed screws. Could anyone point me in the right direction?

It has also become clear that one of my throttle rods is worn as it you can just see it vibrating and this is making one cylinder run a little uneven at idle. Is there anyone in the UK (or US) that sells the bushings, I saw one video and they look like a relatively light press fit and not to tricky, from what I remember the bores are all good.

Thanks

Roger

Re: MFI throttle bushings and set up

Posted: Fri Nov 25, 2022 5:59 pm

by rft218

HI All,

Have taken throttle bodies off and defintely need to rebush them.

I think I can do this myself as have mill and lathe etc at home.

I assume you have to drill out the old bushes?

I can make some more that are a little thicker and press them in.

Cheers

Roger

Re: MFI throttle bushings and set up

Posted: Fri Nov 25, 2022 8:47 pm

by inaglasshouse

Hi Roger

Are these magnesium throttle bodies? I've had a couple of sets of those re-done over the years.

As you mention, you are on a hiding to nothing trying to get decent idle if the throttle butterfly is flapping about and failing to seal the bore, due to spindle / bush wear. Or indeed due to worn bores; they do go, especially after the butterfly starts vibrating - vicious circle as bore wear compounds the spindle play and they don't seal at all, just flap about some more.

If I remember rightly on one set I got away without needing to do anything with the bores themselves. On the other set I needed bore inserts as well as spindle bushes.

From memory the mag bodies originally were not bushed - the spindle ran directly in the casting, which wore rather quickly. If yours already have bushes they have been done once before?

A job well worth doing, anyway. Unless you drive everywhere on full throttle, in which case it makes very little difference!

Good luck, cheers, Richard.

Re: MFI throttle bushings and set up

Posted: Sat Nov 26, 2022 8:15 am

by rft218

Thanks Richard, they are 71 S ones so I think magnesium, they have very small bushes in them, so maybe have been done before.

I'll post some pictures of the journey!

Re: MFI throttle bushings and set up

Posted: Sat Nov 26, 2022 10:52 am

by abzadams

MFI throttle bushings and set up

Posted: Sun Nov 27, 2022 12:54 pm

by hot66

Is the throttle body smooth where the butterfly sits or has it worn?

If all smooth set the butterflies using the manual stops as described in cma and set the rod lengths between each throttle body. If you can then flow test them on the bench and adjust the idle air screws so they are all even ( from memory for this start at 3 turns out ) ….. I’m lucky to have my good friend JohnM do this bit for me as he has made his own flow bench to set them up on .

Then when back on the car they might need slight tweaks to the air adjustment screws to balance fully but in theory should all flow correctly.

From this can then start correcting the lengths of the throttle rods from the main linkage to the throttle bodies on each side

Re: MFI throttle bushings and set up

Posted: Sun Nov 27, 2022 12:59 pm

by hot66

Point being, it need the ‘mechanical’ set up bit to be correct first, eg the butterfly’s etc then play with the air adjustment screws

Re: MFI throttle bushings and set up

Posted: Mon Nov 28, 2022 9:42 am

by MBEngineering

HI Roger

are the flange faces FLAT to start with, as most of the throttle body's I have come across are not and you will chase air leaks with the screws/rods and ?, also to the point of been cracked due to over tightning/lack of support, all the ROAD throttle body's have the bushes fitted and never ran in the Mag caseing,

part No' 901 110 111 00 at £5.94 +vat Each from Porsche

then each side needs ballancing with AIR flow and the throttle stops adjusting and the air bleed screws setting before fitting to the engine as a base setting, then set the rods to match

regards mike

Re: MFI throttle bushings and set up

Posted: Mon Nov 28, 2022 11:26 am

by inaglasshouse

MBEngineering wrote: ↑Mon Nov 28, 2022 9:42 am

all the ROAD throttle body's have the bushes fitted and never ran in the Mag caseing,

Apologies, my fallible memory, please listen to the expert!

Yep, my worse set needed skimming to be flat (as well as needing inserts in the throttle bores).

As Mike suggests, they were bench tested for air flow inc butterfly seal and idle screw adjustment before I collected them, and indeed the rods were set up to operate in sync (also using air flow meter to look at balance on part throttle). I had to promise faithfully not to fiddle with anything without giving the refurb dude a call first... he felt it likely I would not improve matters...

Re: MFI throttle bushings and set up

Posted: Mon Nov 28, 2022 1:05 pm

by rft218

Many thanks all,

I am pretty sure they are flat and seating properly, when I first was setting them up I did a spray around with carb cleaner with it running to make sure there were no leaks and so I am pretty sure that isnt the problem. The first side I have taken off is flat.

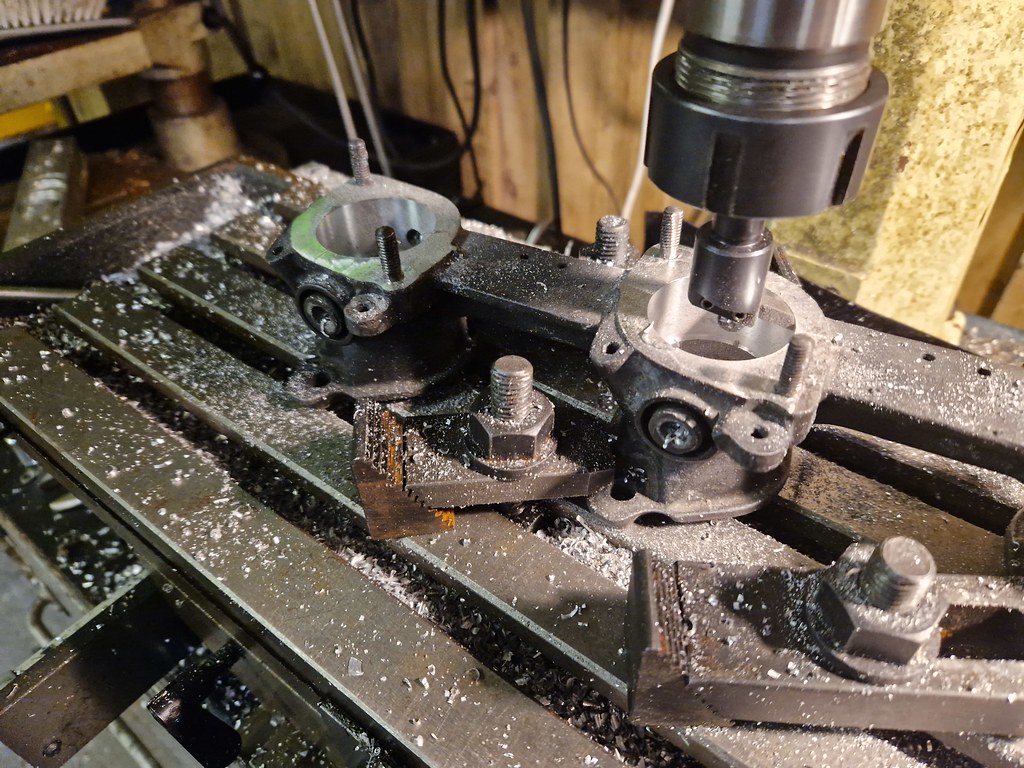

I started on one side, I have made up new bushes to fit, waiting for a 8mm reamer that is long enough to go across the throttles, I only had a 5/16" reamer, which I think is 2 or 3 thou small.

I have also needed to machine out the bores that the throttles run in as on much closer inspection the bore of the one that was jumping around had a pretty big score in it from the butterfly . Bit more of a project in machining than I had hoped but had a quiet weekend so enjoyed the challenge

. My fathers modelling engineering kit that I inherited with mill and lathe with DROs has been in action!. I will post some pictures when I have got them closer.

Thanks again,

Roger

Re: MFI throttle bushings and set up

Posted: Mon Nov 28, 2022 2:12 pm

by MBEngineering

Hi Roger

I would take it you have a surface plate then or use the mill bed, put some 1,000 wet/dry and WD40 on it, then rub the face of the manifold across it 3 time and check for hi spots, I think you will find you may have to turn it over and as you have a mill, a light fly cut should do the trick to sort it out, then dont forget to assemble with some large flat washers on assembly and tighten to HOLD and not to strip the nut

regards mike

Re: MFI throttle bushings and set up

Posted: Mon Nov 28, 2022 3:43 pm

by rft218

Hi Mike, I will do that, I have a surface plate that I think is big enough - I'm all up for spending the time to get it as right as I can first time

Thanks for your time to share you experience,

Regards

Roger

Re: MFI throttle bushings and set up

Posted: Sat Dec 31, 2022 5:28 pm

by rft218

Hi All,

Finally finished doing this and it runs really sweetly. On closer inspection the bores around the butterflies had corrosion and some pitting due to the butterflies wearing away the side walls. So I ended up boring the throats of the manifolds and machining up a set of aluminium tubes that fitted very closely to the bores and then with 38mm bores for the butterflies to run in. I drilled the air hole, and then when in place I glued with Loctite 638, which is a very permanent sealer. Then re-drilled the cross shafts and fitted the butterflies etc, and machined tops of the tubes and face of throttle bodies to ensure they were flat. The bottom, was good so I did with wet and dry on our granite worktop in the kitchen when the wife wasnt around.... When I assembled the butterflies they seem all handed and only fitted one way so should have marked them before disassembly in hindsight!!

Anyway all assembled and the air corrector screws now work well to synch up the set of inlet tracts. Very happy, enjoyed the challenge, cost not a lot but many hours

I will try to post some pictures in a bit when I overcome flickr!

Thanks for the all the advice and to make me get on with it!!

I not have a weird oil leak but will post this seperately,

Cheers

Roger

Re: MFI throttle bushings and set up

Posted: Sat Dec 31, 2022 6:59 pm

by rft218

Re: MFI throttle bushings and set up

Posted: Mon Jan 02, 2023 12:07 am

by hot66

Great news