Page 4 of 4

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 1:34 pm

by PeterK

From the various comments here, is it possible that .....

- the outermost flange (when installed) has the first spigot that sets the starter in the right position

- the slotted bolt holes allow fitment to differing applications, but the spigot always fixes location

- when first fitted, by turning the starter to what was thought to position it closest to the ring gear, the starter was not fully home (located by the spigot), so the throwout was starting from too far away

Just a thought while sitting in Starbucks waiting for daughter 1 to finish shopping

Peter

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 1:56 pm

by sladey

The problem is that when the starter is 'at rest' the spigot hasn't been thrown out, so you've no way of knowing whether it meshes with the ring gear or not.

The spigots don't hold it in place - with the body pushed fully home it could move along the slots. Just to be clear on it none of the issues are to do with it not throwing out far enough or the body being moved back from the ring gear. the only movement has been from side to side - so if the slots were a load bigger then at one extreme it would hit the body of the ring gear every time and the other extreme it would miss the ring gear altogether - but each time the spigot is coming out the same amount and it's plenty far enough.

It's hard to explain this stuff without diagrams

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 2:15 pm

by 911hillclimber

If anyone is an engineer they want to know why anything is not explainable!

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 3:04 pm

by fetuhoe

The pinion gear should generally have the same centre distance from the ring gear or the tooth loading will vary and wear could become an issue due to changes in the depth of engagement.

I have never seen a starter with slotted holes on the mounting flange but this feature should only allow the starter to rotate which shouldn't change the centre distance of the two gears.

I must say that if you can move the starter radially I would worry as it doesn't sound entirely 'christian'.

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 3:38 pm

by Magnum

OK Chris

So....I'm not going to ask you to spread out your produce on this thread after the recent "plonker" post (by somebody else) that resulted in an unnecessary "kerfuffle".....so please could you PM with what you have in the way of leightweight starter motors?

I've learnt that a man should always attend to his own Xmas pressie needs....for the avoidance of great disappointment......

Many thanks

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 6:53 pm

by sladey

OK I think my brain is slowly catching up now.

I’m not sure on the movement now you mention it - I thought it was allowing the whole thing to move to one side as that is how it appeared to me, but on reflection it could have ben rotational movement with the spigot holding it in the right place. But then that doesn’t explain why rotating it has apparently solved the problem

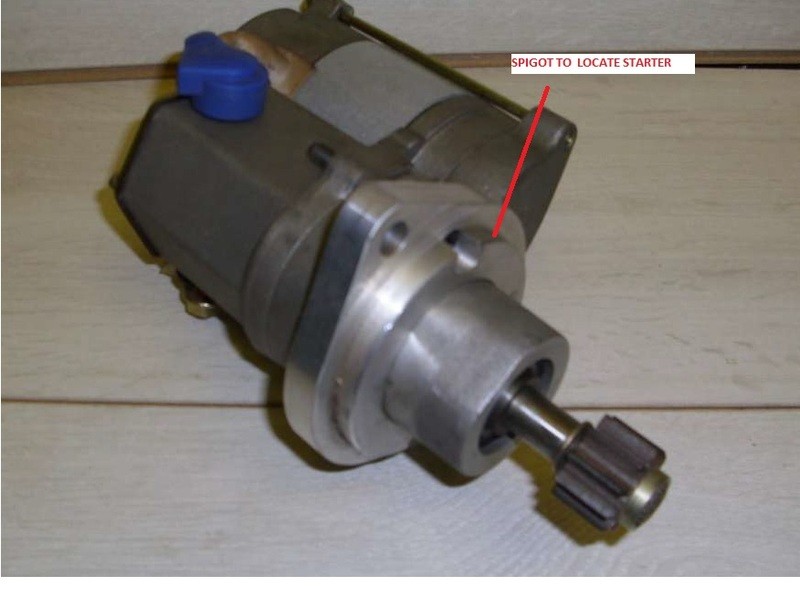

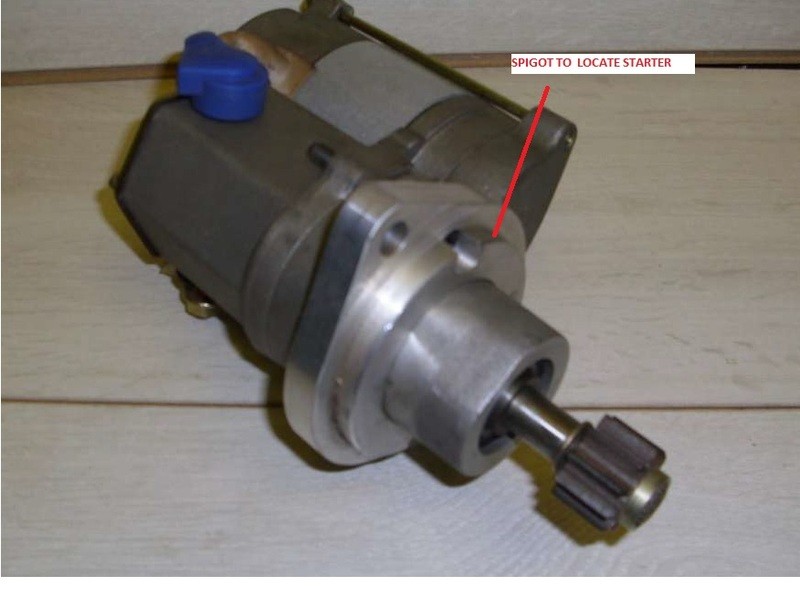

I found this pic of the two hi torque jobbies side by side (new one at the bottom of the picture

Sent from my iPad using Tapatalk

Feckin Starter Motor

Posted: Thu Nov 16, 2017 6:54 pm

by sladey

And this one that shows the slots clearly

So yes it could have been rotational movement - it’s hard to tell when lying on your back in the dark. Whatever movement it was, it seems to have worked!

Sent from my iPad using Tapatalk

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 8:09 pm

by Lightweight_911

I would imagine all that does is allow for a degree of (sideways) clearance for the 'piggy back' motor ...

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 9:12 pm

by MikeB

Surely the answer is that the spigot is a smaller diameter than the hole in the bell housing which would permit the starter pinion to or away from the ring gear, hence the slotted bolt holes ? Or is slightly offset to achieve the same effect?

Re: Feckin Starter Motor

Posted: Thu Nov 16, 2017 9:24 pm

by fetuhoe

Lightweight_911 wrote:I would imagine all that does is allow for a degree of (sideways) clearance for the 'piggy back' motor ...

I would agree - as long as the spigot is the correct diameter. The normal way of allowing the motor to move radially is to use multiple holes to to attach the flange to the body of the starter. This method allows the radial position to be adusted without compromising the inegrity mounting.

If the spigot smaller than the location in bellhousing then the design isn't ideal and we would never fit a starter using this layout. The idea that the starter is allowed to float radially isn't too good.

Feckin Starter Motor

Posted: Sun Jun 19, 2022 6:41 pm

by sladey

Just as a postscript to this thread.

Recently I went to start the engine and got nothing - not even a click. I understand the likelihood is ignition switch fault or starter solenoid not working. It was an intermittent fault (the best kind).

While looking for solutions I found this thread that I started a few years ago!

I decided to replace the starter motor again as well as the ignition switch.

This time I followed the advice on the thread and bought a unit from AES. - a Wosp unit.

So here is the new hi torque unit next to the old one. Note the slotted holes in the old one that caused me some grief

Then I held them side by side

You’ll see the flange on the new one is thicker than the old one. On the old one I had to use an extra washer to prevent the stud from extending into the hex head bolt and stopping you from tightening it. No such problems with the new one.

The only downside to the new one is that the piggy-backed unit on the side of it is the other side and therefore clashes with the heater flapper box pipe

It actually wasn’t a big deal - I trimmed the pipe back and that gave me enough room.

The new starter seems a step up from the last one. Because of those slotted holes I couldn’t recommend the previous one - the one being sold by design911 and made by powerlite. Also I seem to remember having had trouble with it before and most recently it looks like the solenoid was playing up intermittently (though admittedly I can’t prove that) The Wosp one seems a better fit and better made.

Starts nicely now

Sent from my iPad using Tapatalk

Re: Feckin Starter Motor

Posted: Wed Jun 22, 2022 11:04 pm

by rhd racer

Sorry, but I have only just found this thread as recently updated. When I fitted a powerlite high-torque starter years ago to my 901 box in the 914/6, I had to make a 1.5mm aluminium spacer to locate between motor and gearbox (Barrie Martin, 904 GTS on here had fortunately worked this out). It worked fine, but locked solid without (I forgot to fit it after a box change one time). The 901 version did not have slots, but I’ll bet it is a feature of those units as shown by your pic…Not sure why they don’t include a note in the box to this effect….