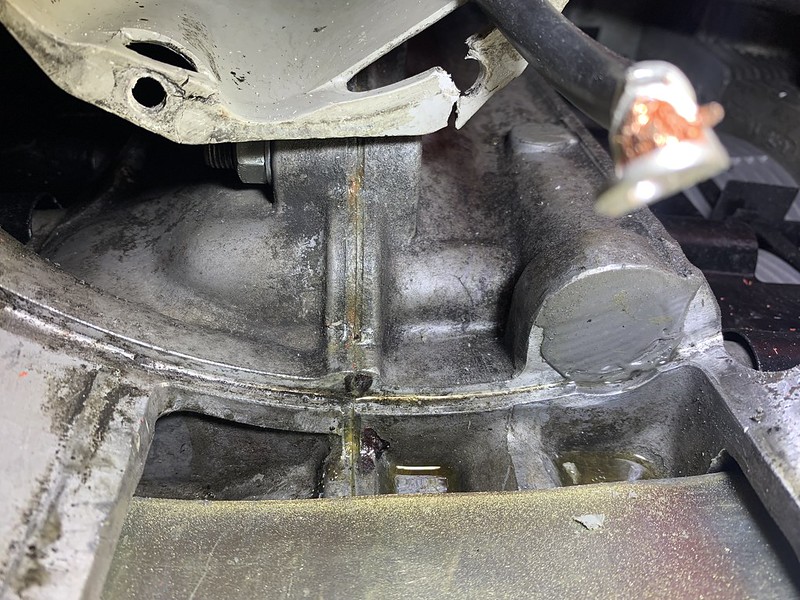

JB Weld hard, strap welded up and time to run the engine. No leaks evident, so I refitted the alternator and fan. Ran engine again, still no evidence of leaks, but will keep an eye on things after my next run out.

Autoheat.

I pulled the controller unit out and my first check was the potentiometer that sits under the temperature setting/control knob

The factory setting (with knob set to position 5 of 9) is 950ohms. Mine was 2.5k, so maybe a tad out. With the knob pulled off, you can adjust the default setting but it was soon fairly evident that all was not well with my pot. I set it to 950, but if I turned the knob fully on then off, when it went back to setting 5, it was nowhere near 950. The range from max to min should be something like 50-2.2k, but I saw ranges from 100-300 and 1.5-2.2, all totally not repeatable. Time to strip the unit down.

The knob pulls off, the stepper motor assembly is retained by 4 cross-head bolts

And the selector assembly by 3 cross-headed self-tapping screws.

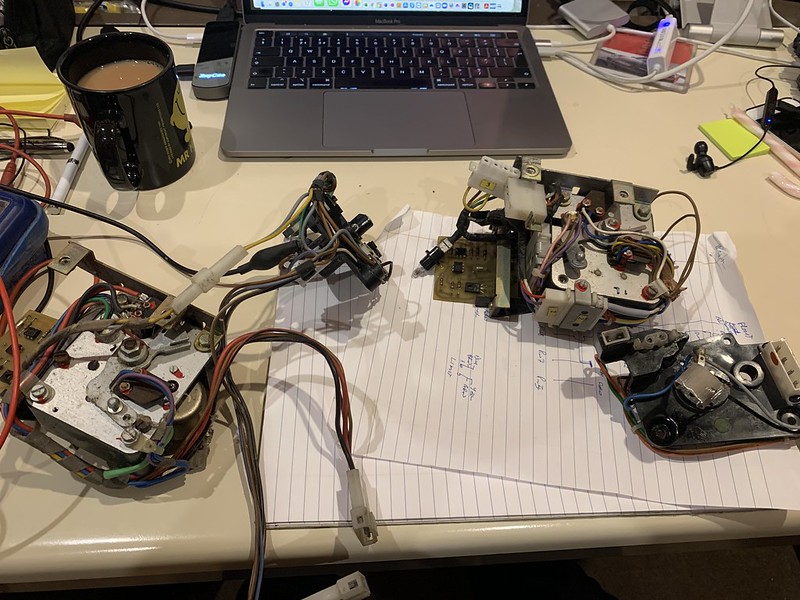

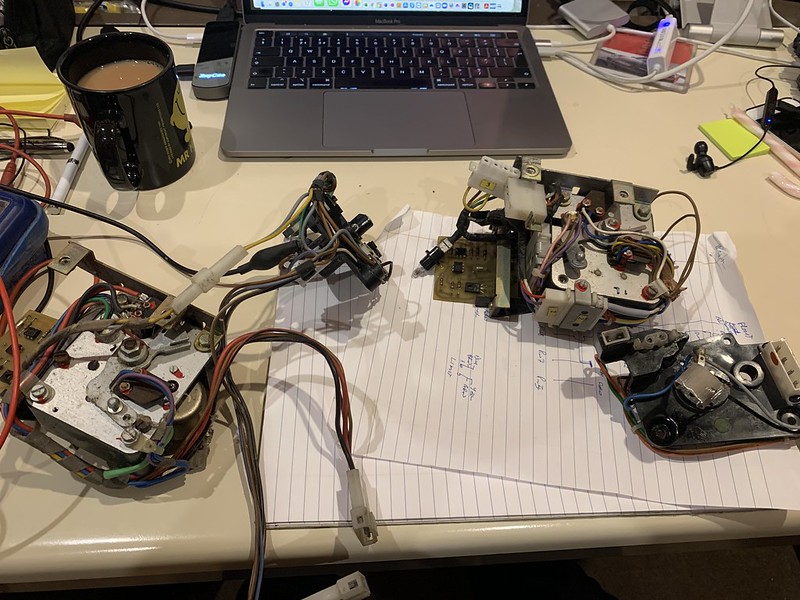

When apart it looks a bit like this

I spent quite a while trying to work out how it all works, with multiple limit switches on both the selector and the stepper assemblies. I also had the benefit (or not) of a later model turbo version, from a car with footwell blowers. That is of course, completely different in how it is wired up, what connectors it has and how many limit switches it uses. The PCBs are identical (part number). The autoheat unit is not included in the Bentley SC manual wiring diagrams and the 3.2 Bentley makes no sense compared to what I had in my hand.

However, at the end of the day, it is really quite simple

A limit switch is built into the in-car sensor circuit. If the selector is set to off, then the circuit is short-circuited, the circuit has no resistance and the stepper motor goes to the stop. Otherwise, the resistance of the NTC thermistor / sensor is added to the resistance of the potentiometer under the selector and the controller decides what position it wants the stepper motor to be in.

The other limit switch on the rotary selector knob (defrost position) makes the sensor circuit go open circuit, and the stepper motor goes to full heat. That explains why if you have a sensor fail open circuit, the autoheat goes to maximum.

As the two units were so different, I decided just to swap the potentiometer from the turbo to the SC autoheat. Having completely destroyed the SC pot, without managing to get it out, we went to Plan B - change the connectors on the turbo box and use that.

Unfortunately, the stepper motor didn’t work, no matter what power I connected. It was sold to me years ago as ‘untested’ by the IBer, but was allegedly working when he bought it. So on to Plan C – use the controller from the turbo with the stepper from the SC.

There are limit switches on the stepper motor assembly, and one controls the engine fan – when the stepper motor is at its ‘off’ stop, the fan circuit is not completed, whereas for any other position, the circuit is made.

All my limit switches worked, except this one. I started disassembling it to replace it with one from the turbo, but in the end and good bit of attention with some fine sandpaper got it working again.

Then it was simply a case of reassembly, starting with an empty case

Add the controller knob ‘scale’

Refit the selector assembly – 3 screws

Add in the stepper motor assembly, not forgetting to make the necessary wiring connections

Attach the control rod (which also needed adjustment to bring it back to factory spec length), give it a quick bench test and it's ready for refitting to the car.

Once refitted, when I select Off, the heating lever moves all the way down. When I select Defrost, the lever is pulled all the way up. When I select a mid-position the lever stays on full heat, until I blow some warm air over the in-car sensor, when the lever moves to a mid-position.

Obvs I’ll need to test properly by driving it and playing with settings and check that it does what I expect, but for now, it looks like a good job, jobbed.

If anyone has some old autoheat parts that thye don't want or need, I'd love to play further with my 'spare' parts