Next Project

Moderator: Bootsy

Re: Next Project

superb

-

mdmax72

- Put a fork in me, I'm done!

- Posts: 1512

- Joined: Thu Sep 28, 2006 8:23 pm

- Location: midlands u.k

Re: Next Project

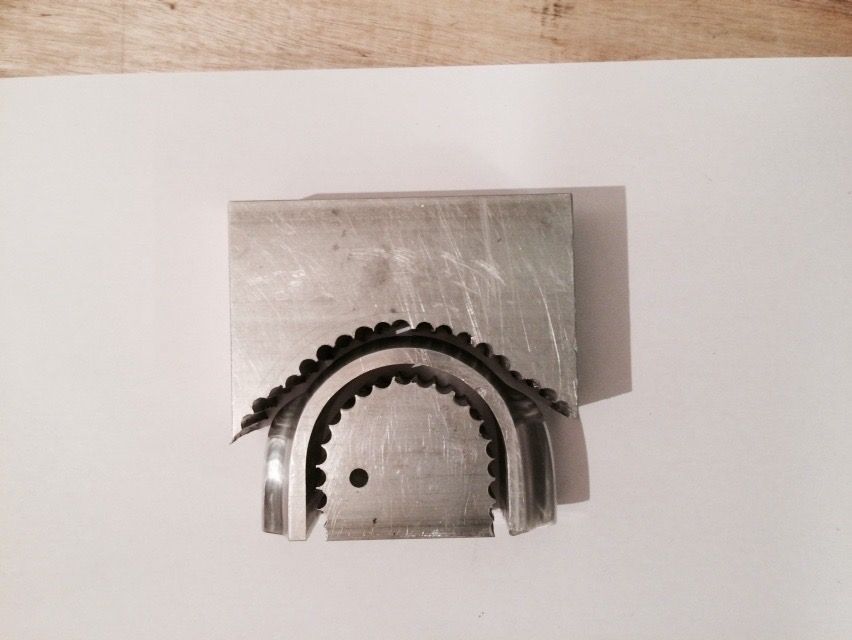

No joy in finding a steering column clamp for a Speedster.

Decided to buy a Coupe clamp as it's the same dimensions, only difference is its taller. So l can use as a profile to make my own Speedster clamp. The Speedster column rubber shows how's much short the coupe clamp is.

I could just make a spacer to make up the difference, but where's the fun in that. Also the cost of these clamps is ridicules. So, figured if l use it as a template l can sell it on and get my £££'s back. So ordered a block of Aluminium at a cost £9 with postage. Now all l need to do is mark it out and cut it out. Easy if you got a cnc machine.

Decided to buy a Coupe clamp as it's the same dimensions, only difference is its taller. So l can use as a profile to make my own Speedster clamp. The Speedster column rubber shows how's much short the coupe clamp is.

I could just make a spacer to make up the difference, but where's the fun in that. Also the cost of these clamps is ridicules. So, figured if l use it as a template l can sell it on and get my £££'s back. So ordered a block of Aluminium at a cost £9 with postage. Now all l need to do is mark it out and cut it out. Easy if you got a cnc machine.

Rich

DDK Member 0547

Evolving Speedster Build

DDK Member 0547

Evolving Speedster Build

-

sladey

- Nurse, I think I need some assistance

- Posts: 8726

- Joined: Sat Apr 23, 2005 9:08 pm

- Location: Nottingham, UK

Re: Next Project

Or a drill pressmdmax72 wrote:Easy if you got a cnc machine.

The simple things you see are all complicated

I look pretty young but I'm just backdated yeah

I look pretty young but I'm just backdated yeah

-

myatt1972

- DDK rules my life!

- Posts: 1445

- Joined: Sun Apr 18, 2010 9:03 pm

- Location: Staffordshire Moorlands

Re: Next Project

Ive got about 4 cnc machines in the cow shed, when you coming to get them gents?....................................only joking

Keith...

73 911e sporto

73 914 2.0l

86 928s S2

85 Mazda Rx7 (TWR)

85 Mazda Rx7

The Bonser fork truck

Volvo V40 T4 (200bhp workhorse)

73 911e sporto

73 914 2.0l

86 928s S2

85 Mazda Rx7 (TWR)

85 Mazda Rx7

The Bonser fork truck

Volvo V40 T4 (200bhp workhorse)

Re: Next Project

skills

-

mdmax72

- Put a fork in me, I'm done!

- Posts: 1512

- Joined: Thu Sep 28, 2006 8:23 pm

- Location: midlands u.k

Re: Next Project

Will it fit in the car Keith, if so I'll have one

What a tool Mark, makes me wonder how l managed without one for all these years.

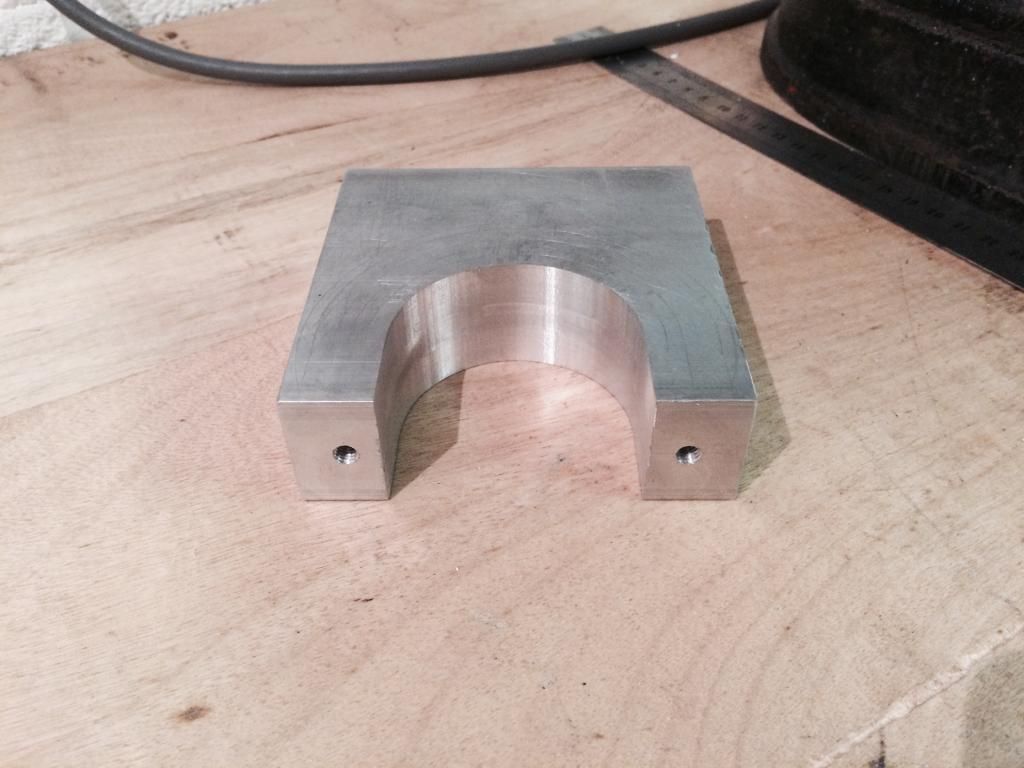

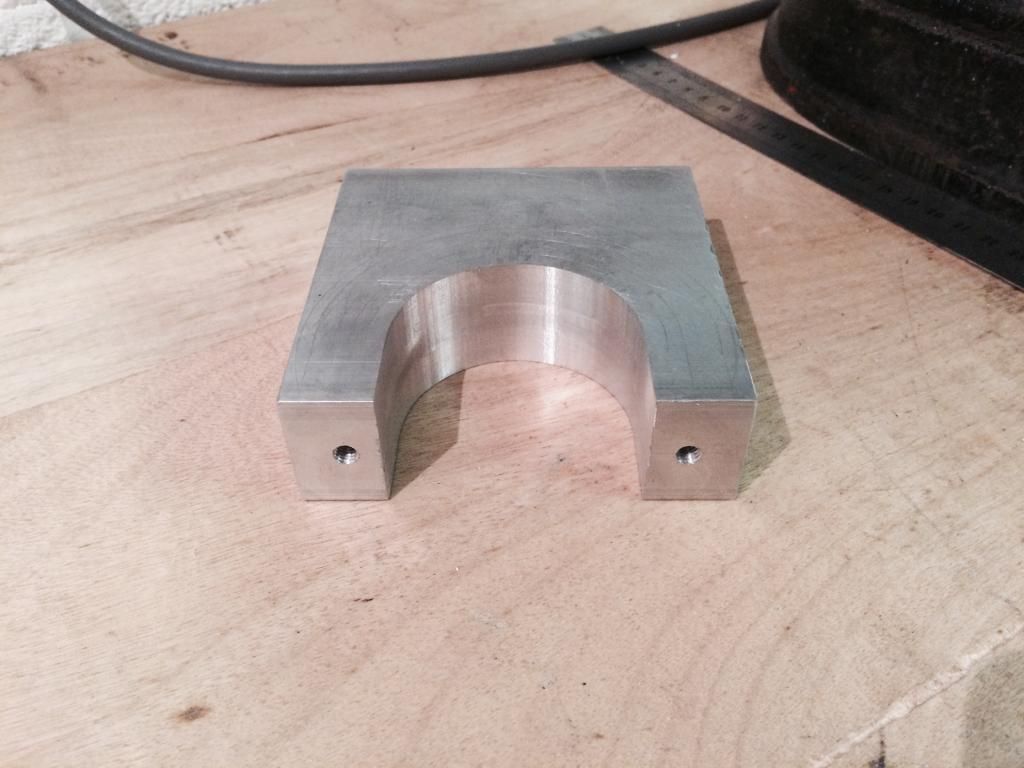

Here's what l got upto last night.

What a tool Mark, makes me wonder how l managed without one for all these years.

Here's what l got upto last night.

Rich

DDK Member 0547

Evolving Speedster Build

DDK Member 0547

Evolving Speedster Build

-

mdmax72

- Put a fork in me, I'm done!

- Posts: 1512

- Joined: Thu Sep 28, 2006 8:23 pm

- Location: midlands u.k

Re: Next Project

Making some good progress with the clamp. Got it to the basic shape, now the fun begins with shaping it up.

Rich

DDK Member 0547

Evolving Speedster Build

DDK Member 0547

Evolving Speedster Build

-

haasad

- Me and DDK sitting in a tree! KISSING

- Posts: 2568

- Joined: Tue Oct 19, 2004 8:46 pm

- Location: Dorchester

Re: Next Project

Nice work.

ddk member# 1527

Austin Healey 100/6, 1957 Fast Road ( now sold)

75 2.7 S backdated to "r" and very light (now sold).

Adria Camper

Buddy McCrae kneeboard.

Friar Tuck kneeboard.

Lots of Bicycles.

Austin Healey 100/6, 1957 Fast Road ( now sold)

75 2.7 S backdated to "r" and very light (now sold).

Adria Camper

Buddy McCrae kneeboard.

Friar Tuck kneeboard.

Lots of Bicycles.

-

sladey

- Nurse, I think I need some assistance

- Posts: 8726

- Joined: Sat Apr 23, 2005 9:08 pm

- Location: Nottingham, UK

Re: Next Project

Awesome work!!

Did you do all that with the drill press?

Did you have a guide/fence for where to do the drilling or was it all by eye using the markings you made on the metal?

Did you do all that with the drill press?

Did you have a guide/fence for where to do the drilling or was it all by eye using the markings you made on the metal?

The simple things you see are all complicated

I look pretty young but I'm just backdated yeah

I look pretty young but I'm just backdated yeah

-

911hillclimber

- Nurse, I think I need some assistance

- Posts: 18924

- Joined: Mon Mar 10, 2008 6:26 pm

- Location: West Midlands

Re: Next Project

A good drill press, and a good cross-axis vise on a rotating base/ dividing head? And a sharp milling cutter as a drill??

Good substitute for a vertical miller.

Good substitute for a vertical miller.

73T 911 Coupe, road/hillclimber 3.2L

Lola t 492 / 3.2 hillclimb racer

Boxster 987 Gen II 2.9

Lola t 492 / 3.2 hillclimb racer

Boxster 987 Gen II 2.9

-

mdmax72

- Put a fork in me, I'm done!

- Posts: 1512

- Joined: Thu Sep 28, 2006 8:23 pm

- Location: midlands u.k

Re: Next Project

Yes 100% all done with the same drill press you have. Did it with-out a guide or fence. Marked it out precisley and drilled out the basic shape, then used some tungsten burrs to start carving it out by eye and feel. Maybe not the right way to do it but it worked for me and surprisingly didn't take to long.sladey wrote:

Did you do all that with the drill press?

Did you have a guide/fence for where to do the drilling or was it all by eye using the markings you made on the metal?

Last nights session results.

Just need to finish the inside of the bracket for the rubber to insert. Not sure how I'm going to do this yet...

Rich

DDK Member 0547

Evolving Speedster Build

DDK Member 0547

Evolving Speedster Build

-

Lightweight_911

- Nurse, I think I need some assistance

- Posts: 16853

- Joined: Wed Nov 12, 2003 10:48 pm

- Location: Worcs/W Mids border

Re: Next Project

Quality work !

Andy

“Adding power makes you faster on the straights;

- subtracting weight makes you faster everywhere”

“Adding power makes you faster on the straights;

- subtracting weight makes you faster everywhere”

-

mdmax72

- Put a fork in me, I'm done!

- Posts: 1512

- Joined: Thu Sep 28, 2006 8:23 pm

- Location: midlands u.k

Re: Next Project

Progress has been slow the last few weeks. Bracket is now complete. Managed to machine the inside of the bracket to accept the rubber and happy with the result. Also got my head round the wiring needed to convert the stalks to work with my loom.

Been putting this bit of for a while, as I'm more of a metal guy and a few of you guys are dabbling in grp. What would you suggest the best way to do the dash. Chesil cut-out for the ignition and indicator body. Why!!! Anyhow it needs filling, what's the best way of doing it. Will all the clocks etc need to come out?? Any ideas welcome...

Been putting this bit of for a while, as I'm more of a metal guy and a few of you guys are dabbling in grp. What would you suggest the best way to do the dash. Chesil cut-out for the ignition and indicator body. Why!!! Anyhow it needs filling, what's the best way of doing it. Will all the clocks etc need to come out?? Any ideas welcome...

Rich

DDK Member 0547

Evolving Speedster Build

DDK Member 0547

Evolving Speedster Build

-

sladey

- Nurse, I think I need some assistance

- Posts: 8726

- Joined: Sat Apr 23, 2005 9:08 pm

- Location: Nottingham, UK

Re: Next Project

Only just caught up with this - awesome work - that is a thing of beauty! (But no answer to your question I'm afraid)mdmax72 wrote:Yes 100% all done with the same drill press you have. Did it with-out a guide or fence. Marked it out precisley and drilled out the basic shape, then used some tungsten burrs to start carving it out by eye and feel. Maybe not the right way to do it but it worked for me and surprisingly didn't take to long.sladey wrote:

Did you do all that with the drill press?

Did you have a guide/fence for where to do the drilling or was it all by eye using the markings you made on the metal?

Last nights session results.

Just need to finish the inside of the bracket for the rubber to insert. Not sure how I'm going to do this yet...

The simple things you see are all complicated

I look pretty young but I'm just backdated yeah

I look pretty young but I'm just backdated yeah