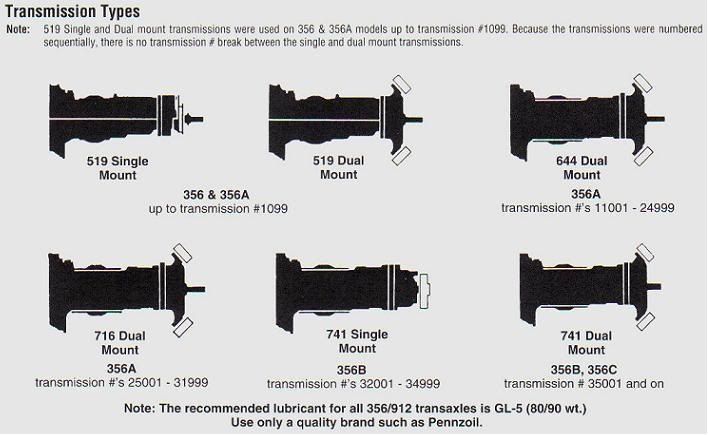

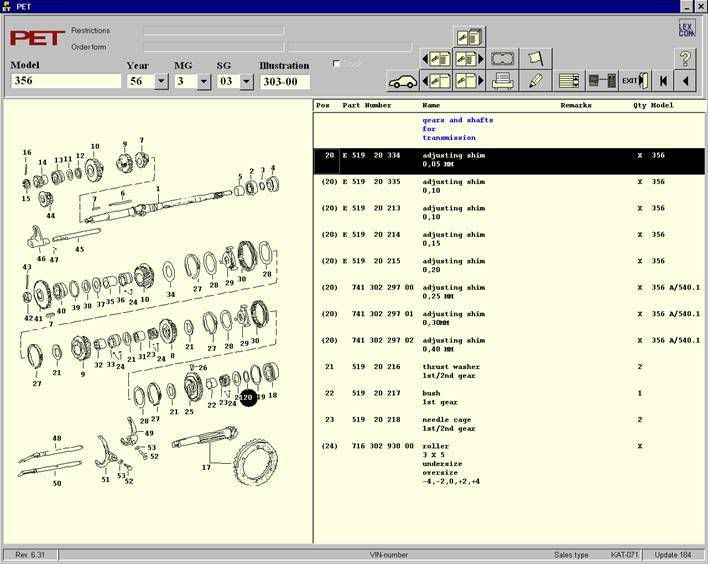

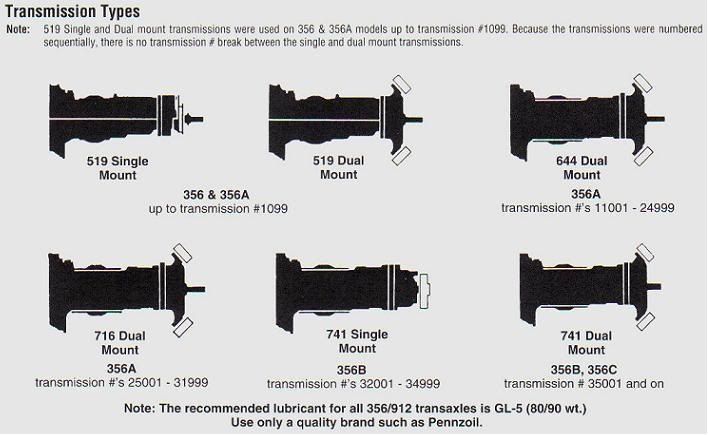

I had to then decipher what type of GearBox (GB) I actually had in the car. I knew I should have a 644 type tunnel box, but that definitely wasn’t what I had. There is some really good info in the 356 Porsche Technical and Restoration Guide vol.1 (the collection of 356 registry articles) about the differences between them all and also here – taken from Stoddard catalogue.

Although it should say 519 up to GB No 10999 not 1099

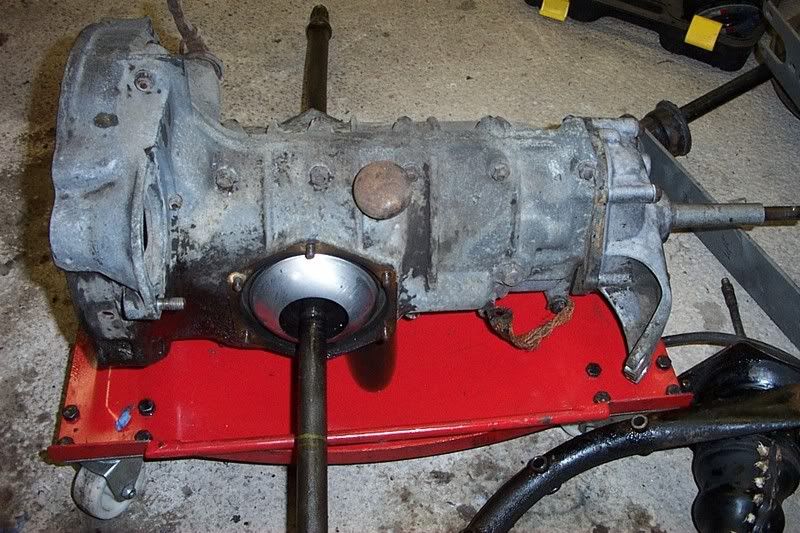

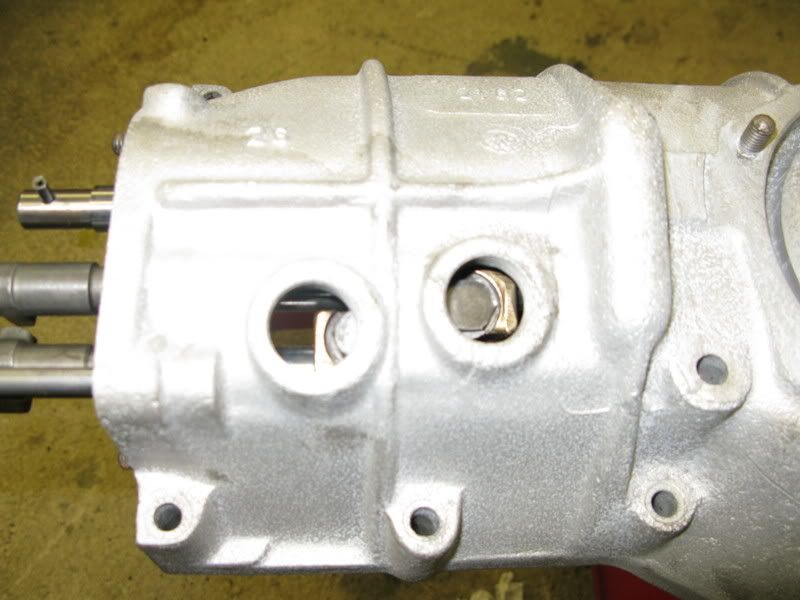

From this I was able to identify my GB number 10575 as a late split case 519 (probably from a 1956 T1 A) with a magnesium case, steel intermediate plate and aluminium dual mount nose cone.

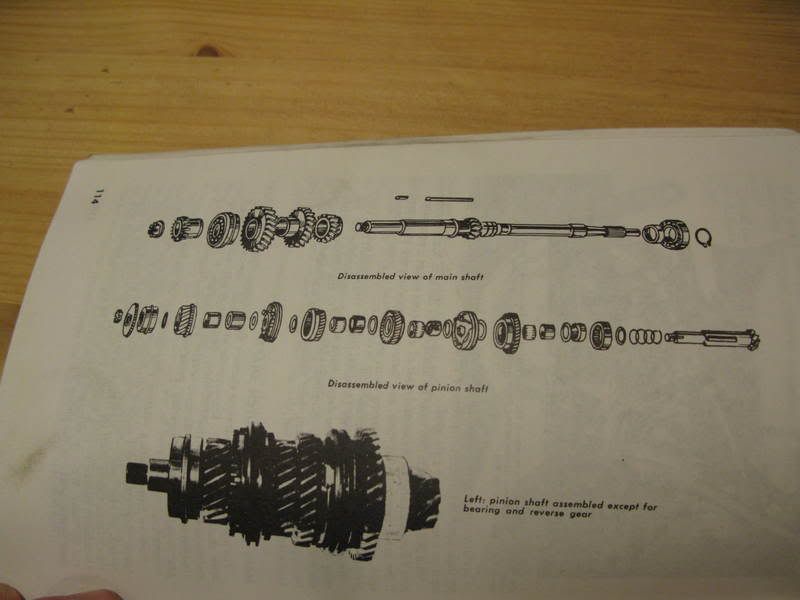

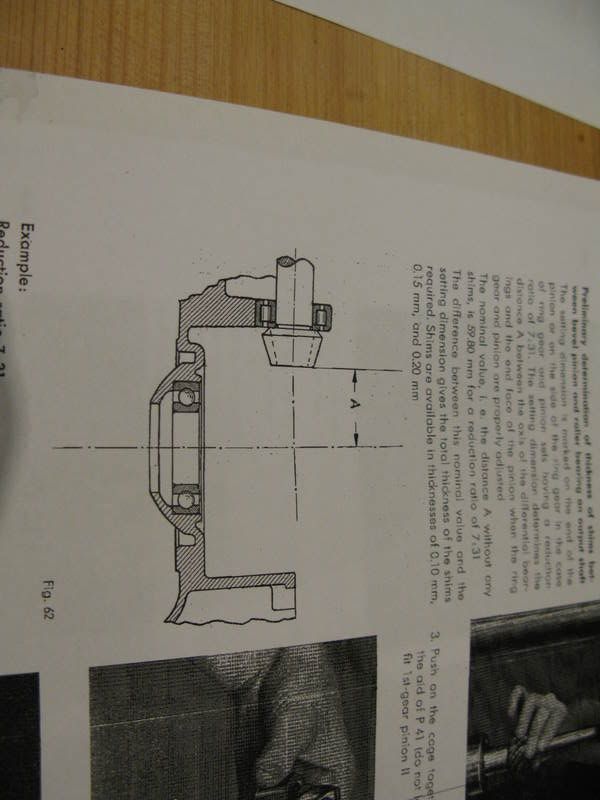

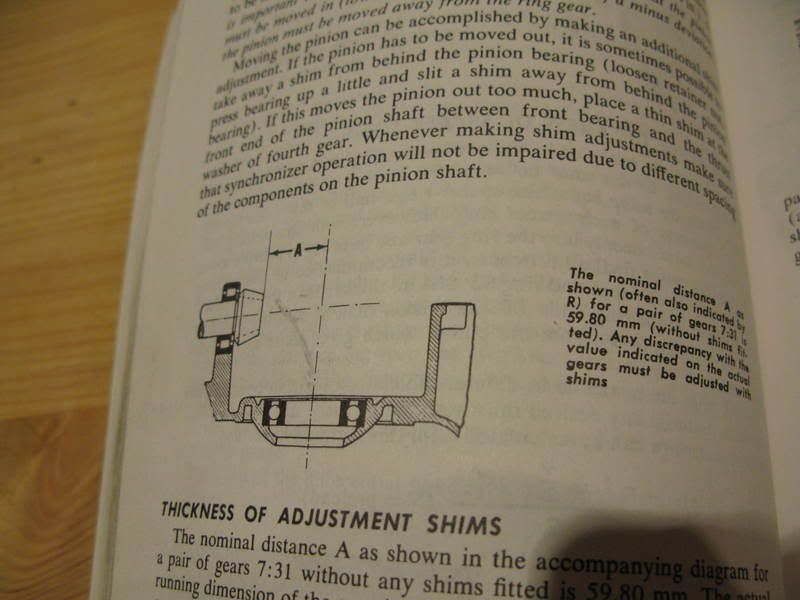

Dismantling was pretty straightforward, see a nut and undo it! What I didn’t do, and should have done, was to measure the thickness of all the gaskets I removed. This would have proved a useful reference later on (2 years later in fact!) when I got around to rebuilding it.

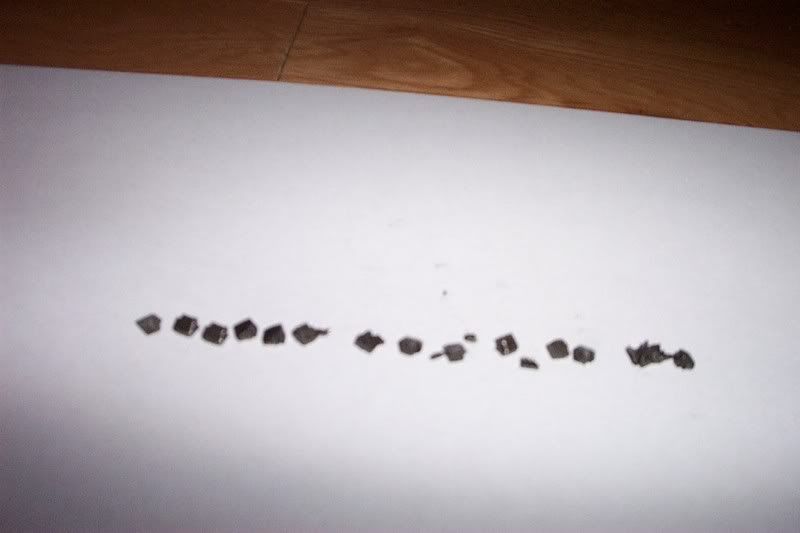

I found this lot in the drain plug which looked a bit ominous!

Second gear had always been a bit “dodgy” but just before taking it off the road it was proving to be really difficult to engage.

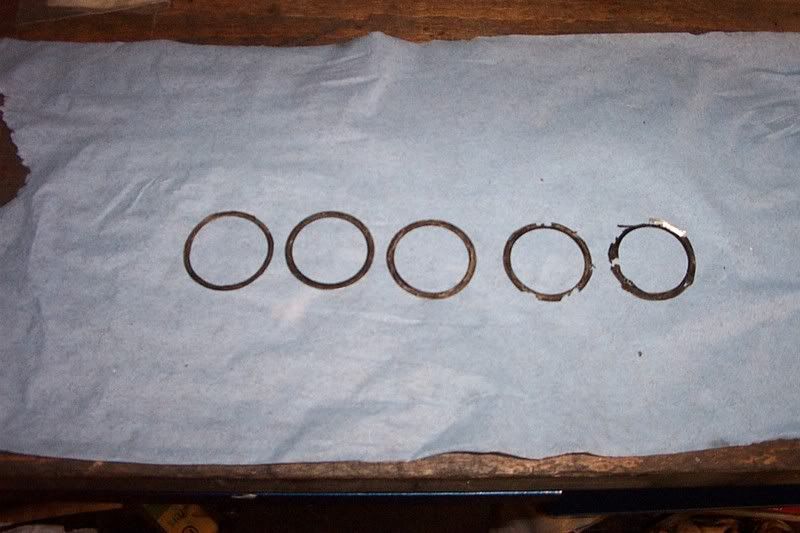

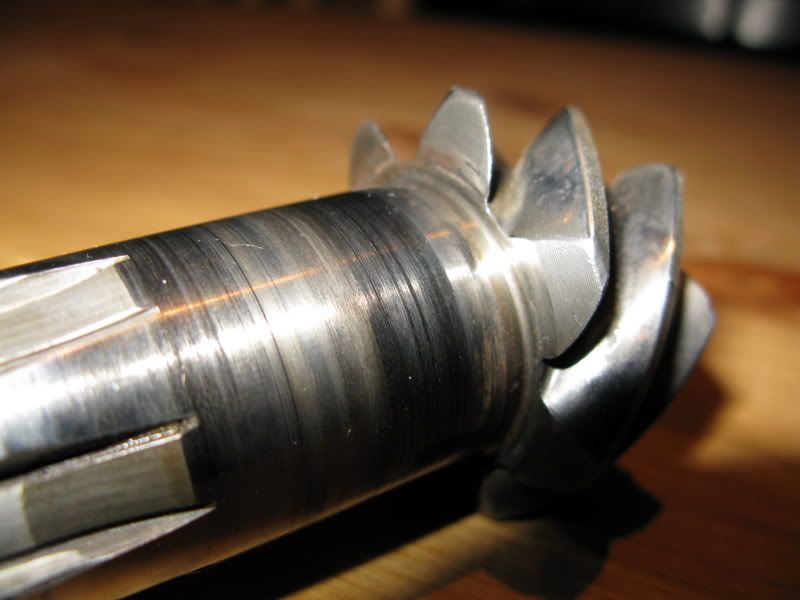

This is what second gear dog tooth ring looked like

(luckily I managed to source a replacement from PRServices

)

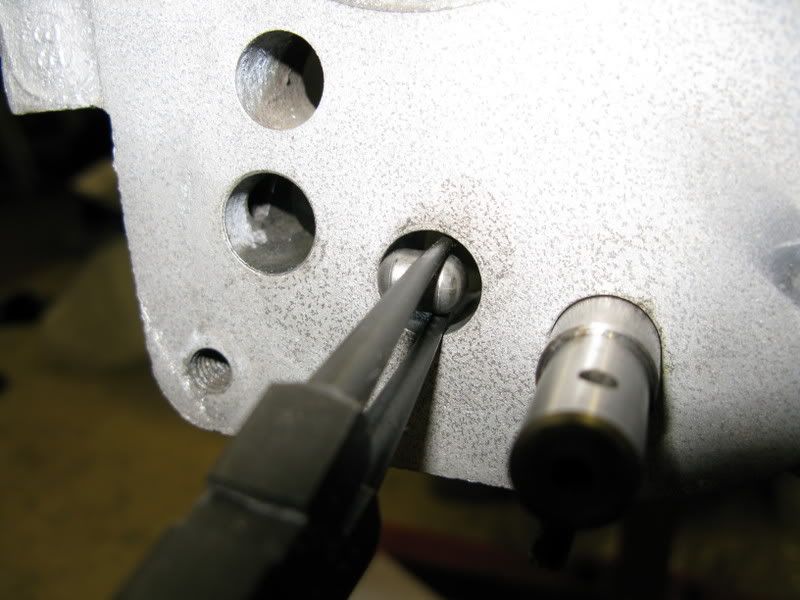

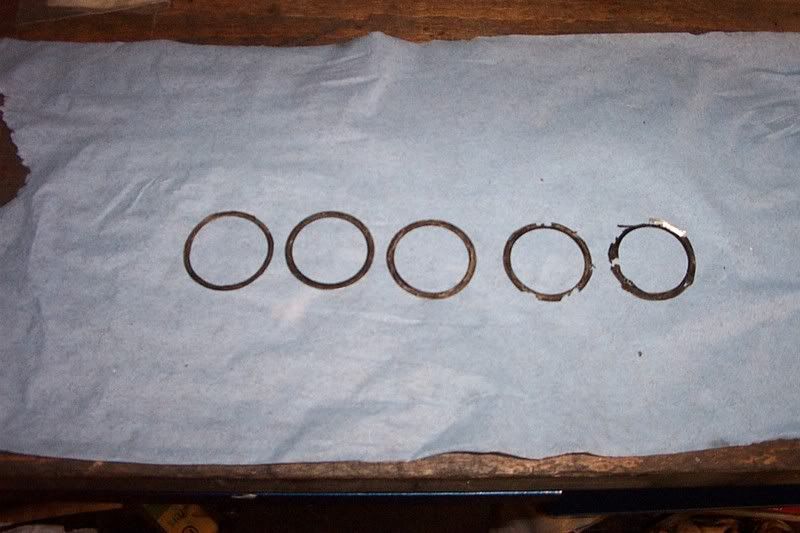

and this is what the spacer shims looked like

So no wonder it wasn’t working too well!

(Its worth saying here that you will need a hydraulic press to disassemble the pinion/main shafts – and when you do get ready to catch the roller needles!!!)