BMW forced Vickers hand by threatening to withdraw all BMW components there and then unless negotiations continued.

3 weeks later BMW announced to the world that it had purchased the rights to Rolls-Royce Motorcars Limited.

For clarity, VW had purchased Bentley and ALL the asset and BMW had purchased the Rolls-Royce “Name” and rights to manufacture motorcars bearing that name.

Graham Morris the incumbent CEO at the time resigned as he’d made a promise to the workforce that the two brands would never be split. Graham stayed on a short while to aid Tony Gott in filling the position.

Since VW had the asset (all the premises, material and workforce) BMW would have to find a new home to build their Rolls-Royce. However they were happy that they had pulled Rolls-Royce from under the feet of Volkswagen.

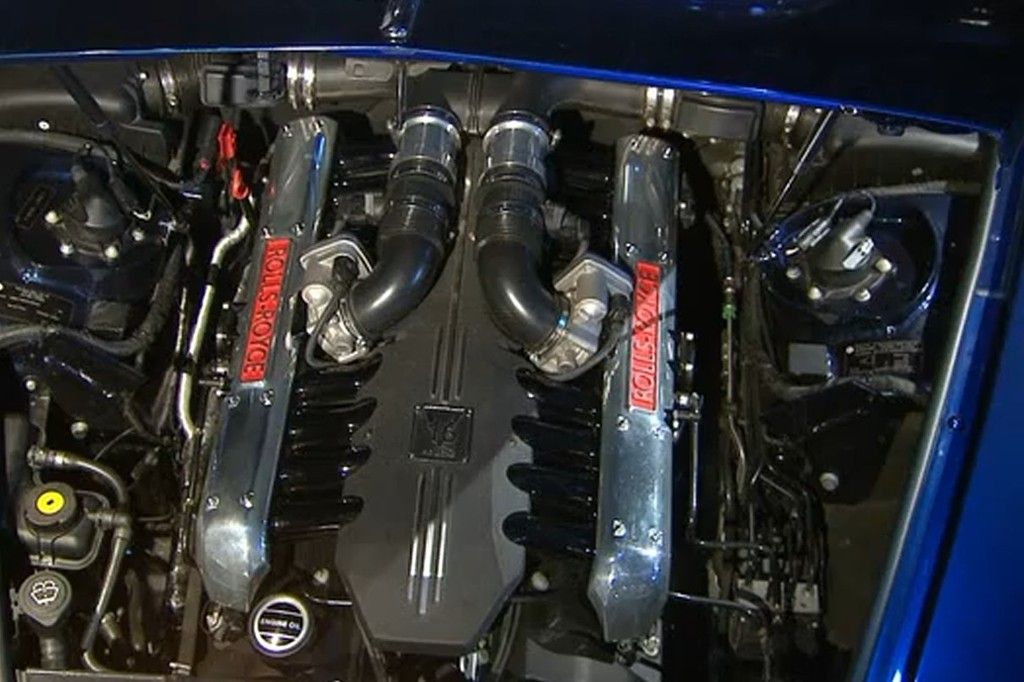

As such the deal with Vickers stipulated that BMW parts would continue to be supplied to Crewe until 2001 allowing the Seraph and Arnage to remain in production during the transitional period.

Unfortunately due to an unforeseen ruling in the sale it soon became apparent that Volkswagen had ownership of ALL trademarks as part of their asset purchase.

This meant that BMW could build a Rolls-Royce motor car but couldn’t use the Radiator shape, the intertwined R-R logo and the Spirit of ecstasy mascot which were now property of Volkswagen.

I’m sure the BMW negotiators had a lot of answering to do when they arrived back in Munich.

BMW had to go cap in hand to Volkswagen and strike a deal to use the trademarks. This allegedly cost them a further circa £30Million.

While all this was going on, a few lose ends to my story at Crewe need tidying up before we move onto the new landlords.

During the courting process of the early/mid 1990’s with BMW & VW, they were both shown numerous Projects as mentioned previously.

One such project was called Bentley Bali (another resurrected name from the Blatchley era). The design studio had a brief for a new coupe. No sooner had the Continental R been launched, the replacement was being considered. By 1997 the designs had been finalised and the new coupe was to be made from Aluminium and composite materials as trialled and tested on the Sultans 6 x Project Grand Prix Coupes. The design was tamed a little and was more akin to the Arnage & Seraph as it needed to fit within the current product family and share their styling influences albeit ready for the next generation of Arnage. It was also to have a folding metal roof as per the ASC developments on project Silverstone.

In early1998 a full size clay was shown to VW by Tony Gott (who was head of engineering at that time) the day later it was announced VW had bought the company.

A few weeks later VW asked for the design to be amended.

A few months later VW put Bali on hold to explore a MSB Platform Coupe based on the VW D1 platform. The current Continental R was revised yet again to fill the stop gap.

Project Bali was laid up……

At the same time Corniche was also being worked upon. The initial replacement for Blatchley’s Corniche was side tracked into the Bentley Azure and no Rolls-Royce updated version was available.

With the development of Project SXB Seraph getting underway in the early 1990’s Corniche had again to be considered. Designs had come and gone from the mid 1980’s and into the early 1990’s without success. With the Millennium looming Rolls-Royce wanted a new Corniche.

With Graham Hull on the design team and his ability to speak a true word in jest and no real progress he said, and I quote….

“Why not do a Porsche and build the new Corniche on the old Azure”

Again what started in desperation and jest, became a reality. But not without first trying to build a convertible on the SXB Seraph platform. Engineering difficulties proved too costly and time consuming to convert the 4 door Seraph to a 2 door convertible.

In reality it was easier and financially better to fit Seraph front body panels to the Azure while retaining the Azure hood and mechanism.

The dashboard and some interior was transferred onto the Azure.

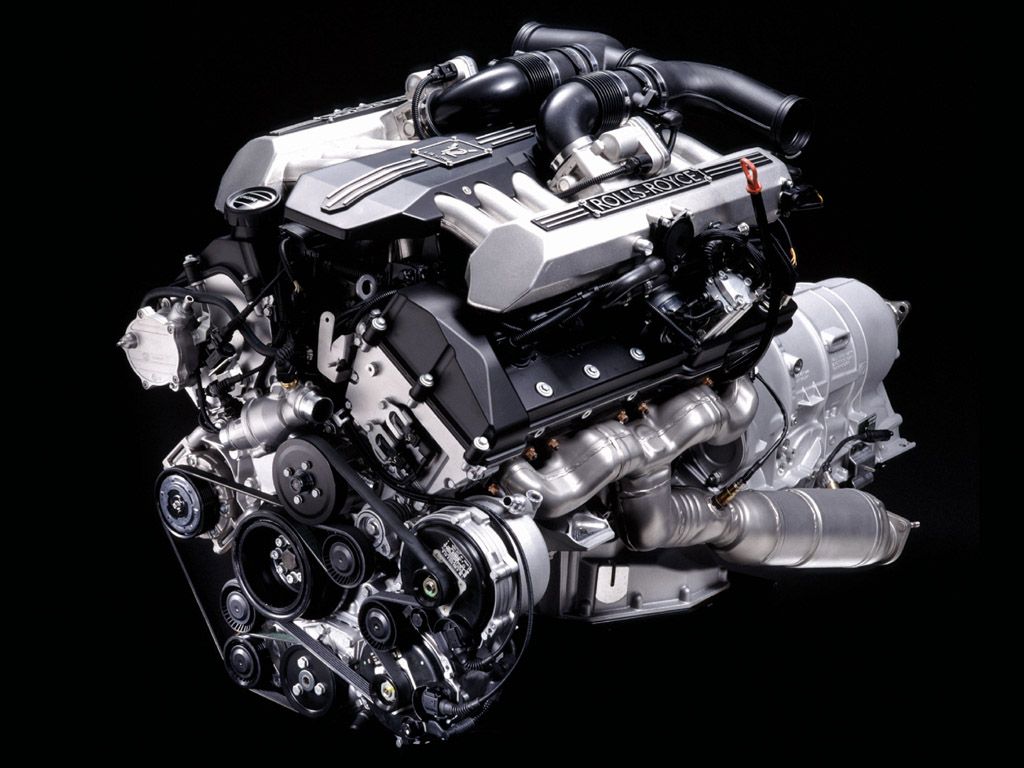

By mid 1998 this proved a blessing in disguise when BMW threatened to withdraw Engines and component supply for Seraph & Arnage, as the proposed Corniche was using the old SZ platform and old Crewe V8.

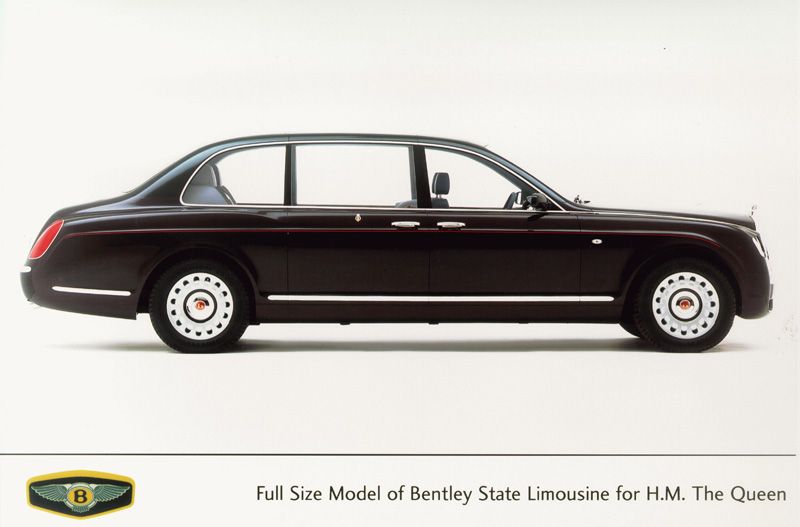

This action removed doubt from VW’s mind over the use of the old Azure platform and gave the green light for the very last Rolls-Royce model to be produced at Crewe under the new ownership of VW, before the right was lost forever to BMW in 2003.

The new and last Crewe built Rolls-Royce was launched in January 2000. The brief to supply the Corniche for the Millennium was fulfilled.

As a quirk of building on the Azure platform and doing it against the clock, all Corniches were completely hand-built.

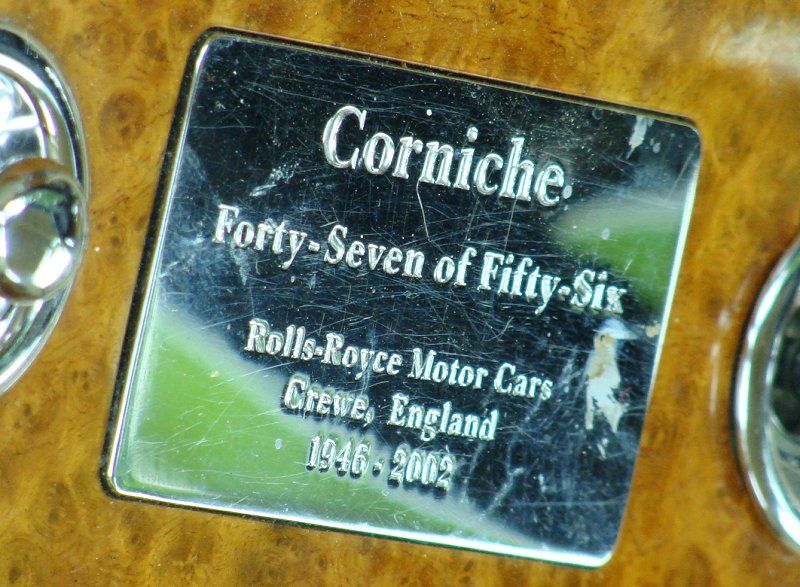

The very last Rolls-Royce Corniche rolled off the assembly line at Crewe on the 30th of August 2002. The total number being built was 374.

The very last Corniche’s bear dashboard plaques with their build number.

Each “Last of Line” car has its number engraved with an “out of 56”. Whereby 56 was the destined number of “Last of Line” cars Rolls-Royce were to make.

By a strange twist of fate only 45 (not 56) Last of Line cars were ever built before the “Cinderella” midnight deadline negotiated date by which BMW took over ownership. The last 11 Crewe Rolls-Royce Motorcars never were to be……